History and development

For many years, WTE has been writing its success story with reliability, high quality criteria, technical progress and precision. Over the years, the company from the Erzgebirge has developed to a leading manufacturer of precision clamping devices.

By integrating the company in the MAPAL Group, a strategic decision was made which ideally prepares the company for the future and guarantees customers and employees many years of security and stability.

History of WTE Präzisionstechnik GmbH & Co. KG

Corporate objectives

Our highest priority as a company is to preserve jobs through growth, economic success and environmental protection.

We regard increasing efficiency and economic growth as a requirement for safeguarding jobs in the long-term. We achieve this with long-term business relationships with our customers and suppliers. Because we want to maintain and preserve cooperation on a basis of partnership and trust as a valuable asset through an open and honest relationship between management, customers and employees. In addition we take responsibility for the protection of our environment with respect to the well-being of future generations.

We regard these aims as guarantees for a satisfactory and trusting cooperation and for a secure future.

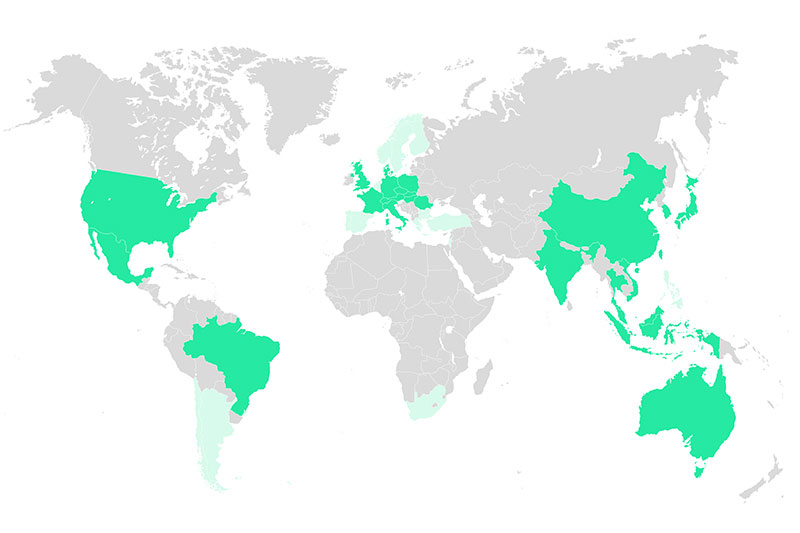

Worldwide presence, international reputation

Contact persons

Sales / Customer Service

-

Andreas Schimmer Sales Manager Email: andreas.schimmer@wte-tools.de Phone: +49 172 3416284

-

Tobias Roth Customer Service Email: sales@wte-tools.de Phone: +49 7361 585 1358

-

Nicole Gurel Customer Service Email: sales@wte-tools.de Phone: +49 7361 585 3211